Bamboob

This was my individual masters project. It was a very open ended brief asking us to choose a subject, research, find a problem and solve it. My chosen area was redesigning the bra.

Timeline

3 months (March - May 2022)

Software

3D scanning, finite element analysis, Fusion 360, Meshmixer, CES

Skills

Sustainable design, textile design, FEA, CAD, User-centred design, mechanical engineering, branding, DFM, report writing, mechanical testing, project proposal, research

Product overview

Problem

This was a multifaceted problem with the main areas being in sizing, comfort, health and sustainability.

Bras are currently sized on two breasts measurements, however there are many more factors that affect bra size, and at least 10 measurements are needed to get an accurate size. Most bras are also sized to assume both breasts are equal, but at least 25% of people have asymmetric breasts that are being squeezed into incorrect cup sizes. This inaccurate sizing leads to discomfort, lack of support and ultimately poor breast health.

If the bra is sized incorrectly it can use the wire to dig into the ribcage or sit on the breast tissue, injuring it and causing lumps. A bra that is big can cause skin irritation and poor posture due to the breasts being unsupported. This lack of support can result in headaches, stretch marks and sagging breast tissue.

The necessity and function of a bra means that it has to be worn, it will wear out quickly and will be thrown away after 6-12 months. Current bras can’t be recycled easily due to there being many materials bonded together that cannot be separated. The bra’s short life span means that it is imperative that it is designed sustainably with its end of life in mind.

Research methods

To research this problem I looked into the bra market, bra production, sustainability, social attitudes, bra history, breast anatomy, bra physics, current bras and the user in a variety of ways.

Bra economics

This was to get an ida of the bra market and what types of bra are preferred by the consumer to get an idea of their mindset and what they look for in a bra.

I also looked into the bras that are marketed as sustainable, what they are lacking and why people aren’t shopping as sustainably as they should be.

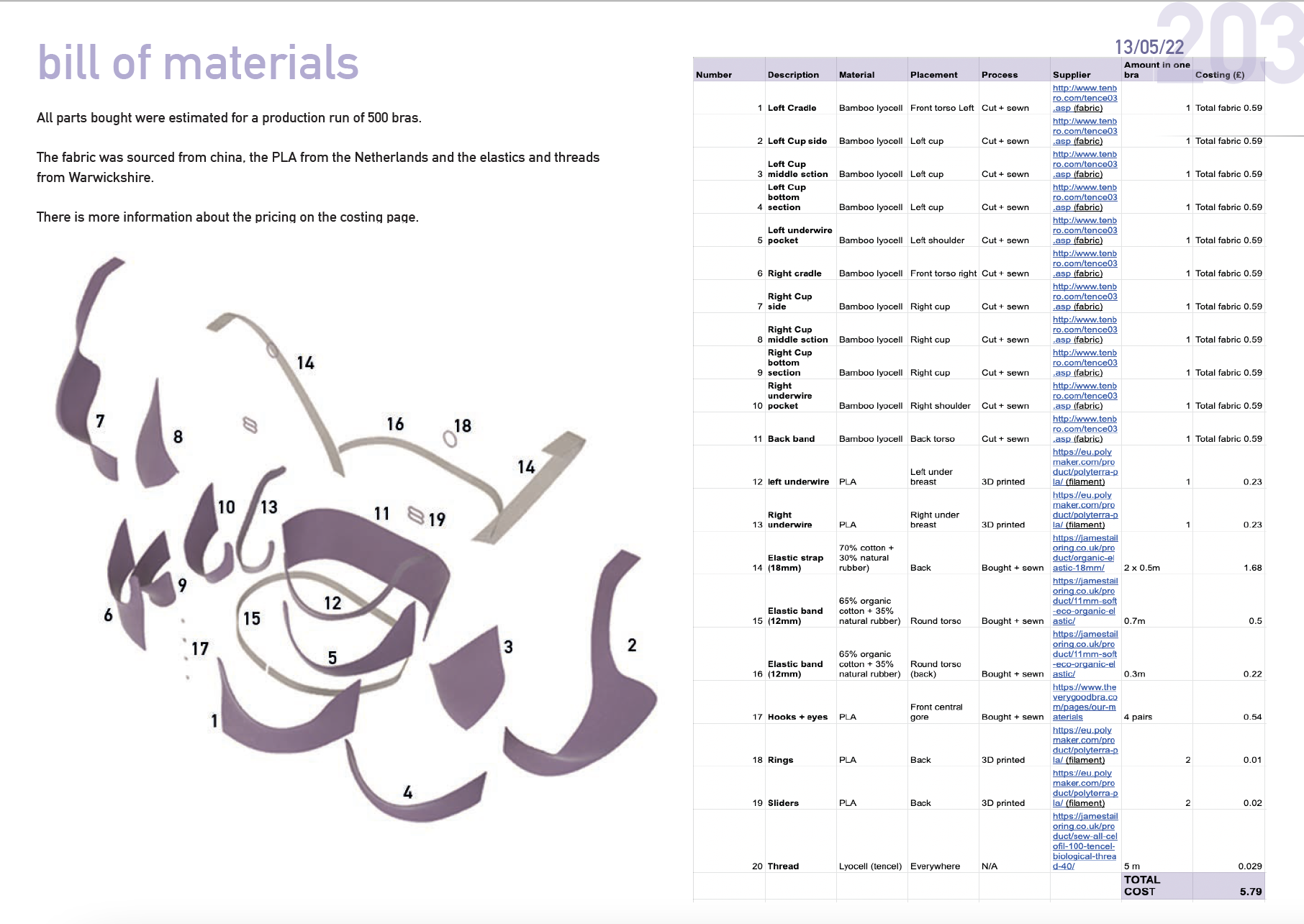

Bra deconstruction

I did this to investigate how many pieces and materials are in a bra (designed to support larger breasts) and how they are attached together. This was to get an idea of the structure, materials used and also the issues in the sustainability of the garment. Answer: 41 components and 4 blended materials.

Sustainability issues

Bras are recommended to be changed every 6-12 months meaning that as they cannot be recycled due to their fabric blends, a lot of waste is created. The reason for this change is because the fabric breaks down, the sharp ends of the underwire pierce through the casing or the breast size changes.

During the production of a (mass produced bra) the whole system is not designed with sustainability in mind. Commonly, different parts of the bra are made in different factories. During the design process they use an ‘average size’ of a 34B and scale the bra up or down. This makes theoretical sense in a mass production setting breast shape and sizing doesn’t work like this. This leads to mis-sized bras which are likely to be thrown away by the consumer before wearing them.

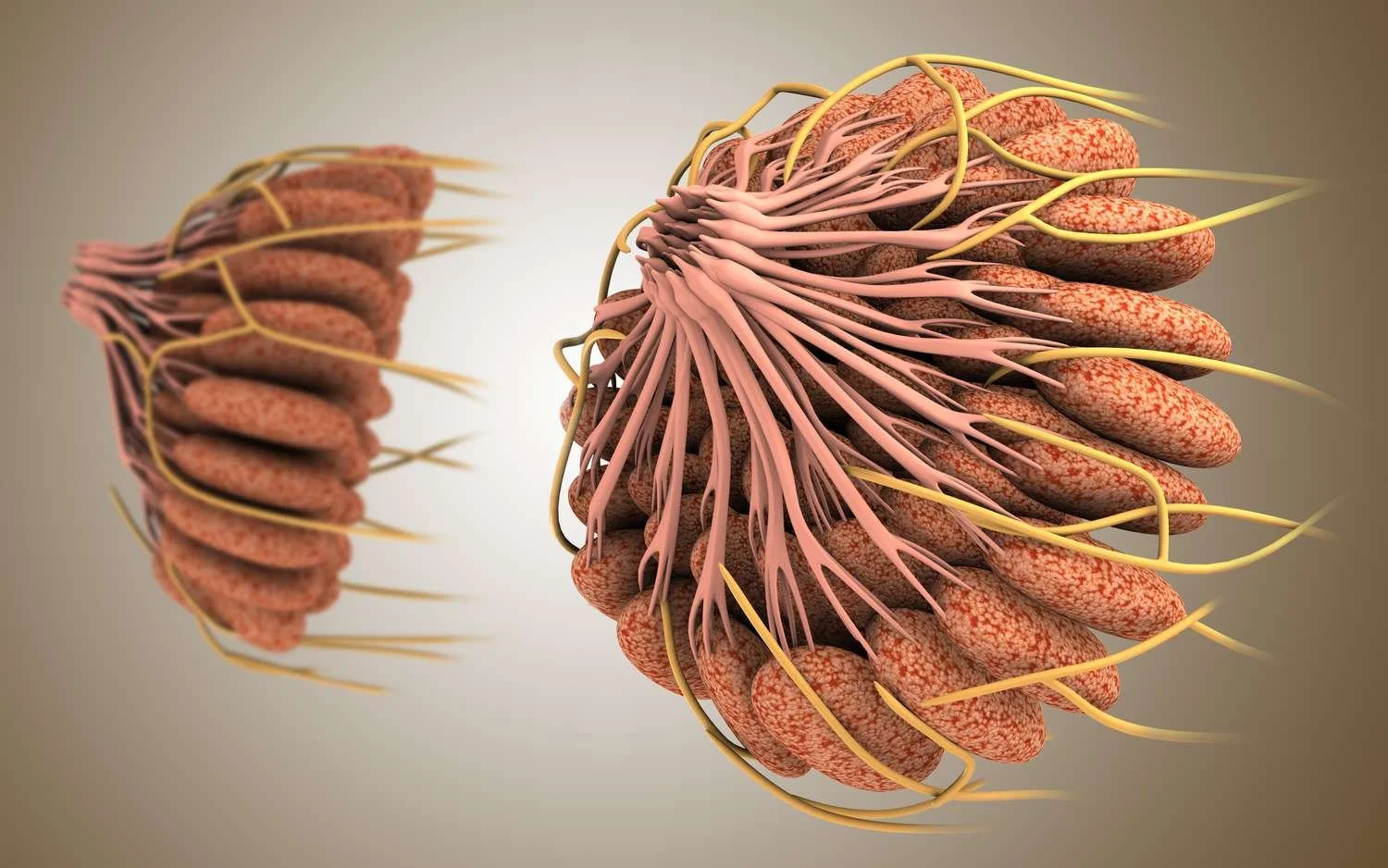

All breasts are different. All are made up of varying densities of tissue, some are assymetric, all breast roots are different even on the same person and obviously many are different sizes. I reviewed many scientific papers to understand to where the load of the breast is carried, how it effects the muscles and the anatomy inside the breast itself.

Mindmap of sustainability issues to be addressed

Breast anatomy

Breast root

The breast root is the place in which the breast tissue protrudes from the body - basically its a curved line under the breast. This is where the most supportive and comfortable underwire should sit. Your breast root is not either wide or narrow it is a spectrum and they are the two extremes. To illustrate how different breast root shape can be this is a trace of 10 different 34D sized people, none of the lines are the same so how can they wear the same sized bra as size accuracy of the underwire is so important for comfort.

Competitor analysis

A solution to make underwires more comfortable is to make them from a shape memory alloy to conform them to the breast root. By using a 3D wire instead of a flat wire, they can be moulded around the ribcage instead of putting tension on it to hold it in place. Another solution that is commonly found in sports bras is to create a tighter weave where the underwire should be to increase the tension on the fabric in that area.

Calculating breast volume

Breast movement

One of the purposes of a bra is to reduce movement by using the tension in the cups to carry the force of the breast.The movement of the breast was found to be in a butterfly like pattern, so in order for my bra to fulfil its duty it need to be designed with this in mind

Bra physics

It is important to understand where the breast exerts a force on the bra to work out where to focus the redesign on. From my research I found that: the breast exerts a radial uniform pressure on the bra cup, the tension in the cup from the strap and the underwire lift the breast and this tension is translated around the body for 80% of it to be held at the back of the band.

Talking to experts

I contacted bra fitting experts to understand current bra fitting and contacted a start-up making a bra fitting AI to understand the problems they were solving and facing during their research. To understand the anatomy further I contacted an osteopath.

Underwire issues

The purpose of an underwire is to support and mould the breast, as well as giving them lift and reducing back pain. They should keep tension in the cup fabric (so the breast weight is distributed evenly across the band and not in the straps) and fit snuggly along the breast root. They aren’t aways successful though and a poorly fitted underwire can cause many problems by crushing the breast tissue or digging into the armpit.

User-centred design

LO-FI measurements

To understand the size discrepancies further I took measurements of the the breasts of a focus group including volumes and sizes. I got them to take measurements using a measuring tape (right) then asked them to put each breast in a pan of water allowing it to displace into the other pan for me to calculate the volume. I then compared the measurements to each other, assuming that they would be in the same order each time.

User group decision:

Larger breasted people, especially those with asymmetric breasts, of any age. No matter how socially acceptable not wearing a bra becomes there will still be a large amount of people that will have to wear a bra as a health necessity.

The user is the most important stakeholder in this project, so I used many different research methods to understand of their needs and inform the direction of the project. I initially started by holding a focus group and asking them to complete a radar analysis. I split the radar into 6 sections: comfort, sustainability of materials, support, durability (life of the bra), style, versatility. I then made the inner most circle primary requirements, secondary requirements and the outer tertiary requirements. I asked them to only put one in primary, two in secondary and three in tertiary to make a hierarchy of attributes.

Survey

To get to know my user further, I sent out a survey, asking them of their experience with breasts and bras. The response was massive, highlighting how much of an issue ill-fitting bras are. 167 people responded this coupled with my other research allowed me to narrow down on a problem and user group

Survey analysis

Q: Do you ever struggle to put a bra on?

Questions

Q: What is your favourite style of bra?

Q: What do you look for when buying a bra?

1) Age, bra size

2) How many different sized bras do you own?

3) Have you ever been measured for a bra?

4) What is your favourite style of bra?

5) What are the most important things to you when choosing a bra?

6) Is one of your breasts a different size to the other?

7) Describe how you put a bra on, do you struggle to put it on ever?

8) When do you wear a bra?

9) Do you get back pain from your breasts?

10) Do you find bras uncomfortable?

11) How often do you buy new bras?

12) Why would you throw a bra away?

13) How many bras do you own?

14) How many of these bras do you wear regularly?

15) How often do you wash your bras?

There isn’t much of a significant difference apart from in the oldest age category where a third of them said it was hard to get a bra on, some opting not to wear one at all because of this.

Most said that their biggest struggle was the hooks and having to bend their wrists (and shoulders) awkwardly around their back if their breasts were larger.

Sustainability opinions

I felt peoples opinions on sustainability was an important aspect to explore as I wanted it to drive my project but i needed to see if the user felt the same. I proposed these questions:

What do you think the main sustainability issues with bras are?

When you buy a bra, do you think about its life cycle (how it’s made, what the materials are, how long you’ll have it, how you’ll dispose of it)?

How important is the sustainability of your bra to you?

How do you currently dispose of your bra?

Why do you dispose of it?

Result

Q: Do you find bras uncomfortable?

After analysing all the questions related to discomfort I came to this conclusion: Underwires are a primary cause of discomfort as are ill-fitting bras. Those that were measured correctly seem to be more comfortable. Those that refreshed their bra regularly weren’t more comfortable than those who didn’t. Therefore, focusing on material durability to make the bra more sustainable is a good idea. Those that wore underwire didn’t seem to have less back pain but found bras more uncomfortable. Therefore in terms of the comfort improvement I need to make in my new bra, I need to avoid steel underwire or change the material of it and use an accurate sizing method.

Examples of measurement

Ordered everyone by size in current bra theory, everyone should be always on the same row but they weren’t, highlighting why the current sizing method isn’t good enough

Some trends:

• Right hangs lower (or same height) on almost everyone

• Left is bigger (or same) on everyone, this is shown in volume calculations and in circumference at chest calculations

• Everyone is wearing the wrong size, but most are wearing the correct ‘volume’, the band/cup size ratio is wrong.

• Cup volume measurements actually don’t correspond to actual breast volume

Support is more of a concern in larger breasted people, almost equalling comfort, which makes a lot of sense, with style not being as important. Durability is equally as important with smaller and larger breasts. Versatility isn’t a concern really for those with larger breasts, this could be because they wear the same supportive bra often rather then changing it up.

Understanding the user

To get an accurate representation of how the breasts affect the spine, I wore a 36HH bra and filled the cups with 2.1kg of water (the average weight of that size of breast). I then did my day, cooking, studying, exercising etc. to see how my life was impacted and to see if it really didn’t cause me much back pain. There are obvious limitations to this as ‘breasts’ weren’t attached to my body and the fact that they were probably a bit bigger volume wise than actual breasts of that size as water is less dense than breast tissue.

In terms of the inadequacies of the structure of the bra. I found that I almost wanted to lift the bra at the bottom with my hands to make it droop over the underwire less. The bottom felt like it needed more material to support the breast and take the weight off of my shoulders. In addition the steel underwire was very painful and dug into my organs quite a bit.

My brief

There are many issues with the current bras of today, discomfort and a lack of support causing pain for the wearer, as well as the waste created by the disposal of bras and the lack of sustainability in the manufacturing process. Wearing a bra is not something that can be avoided, it is an essential item of clothing for a lot of the population, that isn't as good as it should be currently. What type of bra, the materials that are used to make it, and the support it offers is something that can be improved.

Summary of issues:

Lack of sustainable materials in most bras (especially for those with larger breasts

Many components and many materials in each bra

Not designed for asymmetric breasts

No consistent sizing

Not tailored to the individual when every breast is different

A bra is not for life: its for 6 months so it must create minimal waste

Additional requirements

• Needs to have less components than a normal bra to streamline the manufacture of it

• A custom process that has the potential to be scaled up with future development

• Try to make it be able to be washed in the washing machine, unlike normal bras.

• Reduce waste in all stages of the manufacturing process.

• Be aware of environmental standards and keep them in mind

Affinity cluster to help with problem grouping

5W’s

Who The larger breasted, especially those with asymmetrical breasts and those that struggle to fit into conventionally sized bras

What A supportive, comfortable, sustainable bra

When To be worn everyday, doing daily activities - not specialised for sport or sleep etc.

Why There isn’t anything on the market that does all these things in one product, they normally tackle one or two issues only.

How Using a way of sizing the bra taking more than 2 measurements to make it more accurate and creating a novel support system and underwire. As well as using sustainable materials to create the bra.

Initial ideation

String + nail underwire

My idea was to create a weaved structure inspired by nail + string artwork. The point was to create a structure that isn’t the regular rectangular weave, in the hope that this gave the material more strength like an underwire, but meant it was still comfortable and flexible. I placed the nails in an underwire shape, the weaving of the string was successful however, removing it from the nails was not. As the string was under a high tension and each length went to many nails, it fell apart even if I knotted it at the ends.

3D knitting

Modular bra

The bra is designed for disassembly, so when one part wears out it can be replaced, meaning the bra will not be thrown away so quickly, thus is much more sustainable. It could also help people with asymmetric breasts as the cups would be separate, so could be different sizes, However this could cause other posture/pain problems down the line. This would be a relatively easy option to take forward, but I am unsure how rewarding the project would be.

Generative bra

This bra uses generative design to create a bras with the essential, personalised support for each user. I envision it to use one type of fabric or knit for the supportive sections and another type (that’s less strong) for the areas that don’t need as much support. I think this idea would be quite difficult, however, would be very interesting development if it was possible.

This idea is knitting a bra from a 3D scan of the body, either in one piece or in multiple pieces , sewn together. The pattern could be created from points or parameters inputted into some pattern creation software and the knitter could make a bespoke bra tailored to the person. This may have been quite hard to create the algorithm for this and did rely on the availability of a 3D knitter - which was impossible to find. However it would have allowed for mass production of custom made, comfortable sustainable bras which would have been very interesting and maybe something to pursue in the future.

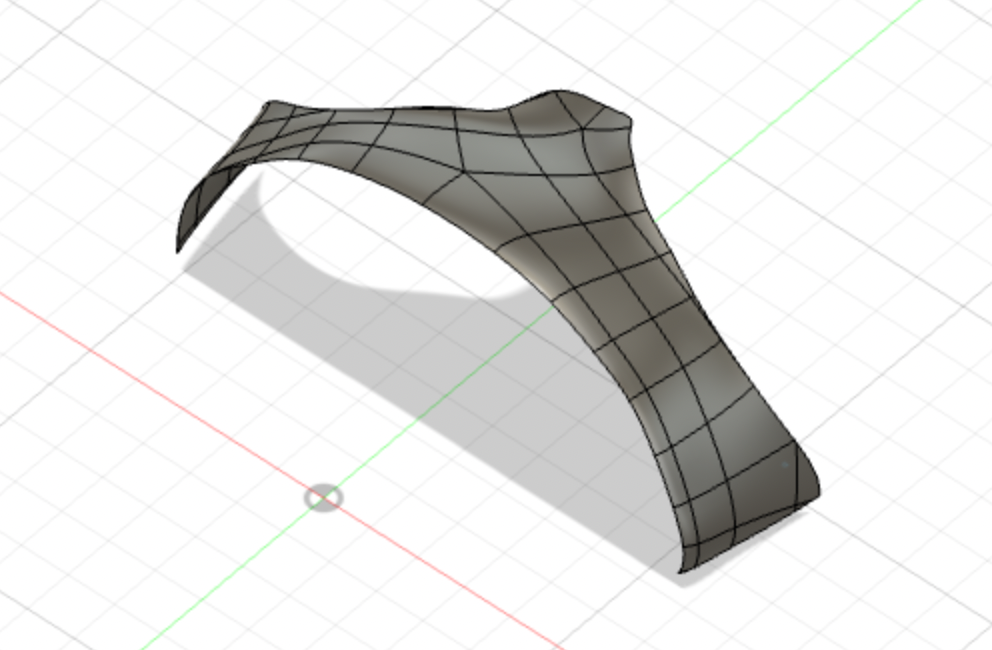

3D scan research

As I wanted to make a personal solution, I decided early on that my solution would need to bespoke. Most of my initial ideas included 3D scanning and I wanted to use all the digital methods at my disposal, so I began 3D scanning my models and manipulating their scans on fusion 360.

To practise the technique, I got someone else to scan to me. Instead of just the front being scanned I got them to walk the whole way around me, so my whole body would be in it, to give full dimensions that I could hopefully make a well fitting bra from.

The model was exported as an .stl file and cut

The mesh was repaired and the holes filled

Then I converted it to an organic t-spline body using the product design extension in fusion. This allowed the surfaces to be fluid shapes and made the contours obvious, instead otherwise using triangles or squares.

Using the line of the organic body, I projected the geometry and made the sketch using the projection as guidance. Here I’m making the cradle.

This is then extruded through the whole body (and a new body is made). The new body is the one the be split and the tool is the scanned form.

The split body tool is used to cut it out and it is cut in half.

Offset the outer surface and extruded it a thin body. Which I then saved as an stl and exported to Meshmixer.

Once the thin parts were in Meshmixer, I unwrapped them. They were then exported to illustrator as an svg file.

In Illustrator I put them on an a3 sheet to print. When actually using them for manufacture this will be a lot more regular, have seam lines on them and indicate which piece goes to which.

Refining + proving the scanning method

I experimented with many different taping techniques and found this one to be the most reliable: scoop around the breast (outside only for smaller breasts and outside and inside for larger). For even larger another tape was necessary up the centre of the breast over the nipple.

To prove that 3D scanning was an accurate way of measuring I scanned the same people I measured previously (and more) and compared the result.

All of the bust and apex measurements are between 0.5 - 4% deviation. The scan therefore needs to be scaled down by 4% to allow the bra to fit tightly around the bust (so the bra is still supportive) as the measurements taken by the users will have been a comfortable size for them.

Shows the volume comparison table with the scan. This was not as reliable as the physical measurements with most of the volumes having 0-18% discrepancy. This is a large percentage difference. Despite this, most of the asymmetries are captured in the volumes. The deviations concur with the original volume measurement’s asymmetries. Thus, scanning is an accurate way of measuring, it just needs to be scaled and the pan method was not.

Making bra shapes from scans

To investigate the accuracy of the scanning technique, I made 5 differrent bras, cutting the scans up in a number of ways.

FEA + modelling

To investigate where the loads were acting most on the bra I inputted the data for various sized breasts into an FEA simulation. In order to create a successful simulation and have something to compare the data to, I had to come up with a way to theoretical model of how the to calculate where the forces are acting on the bra.

From the bra physics + breast mechanic research I knew where the overall force was acting on the bra.

I used the simulation result to trace over to inform the final design. The higher stressed areas were gone over in bright blue marker and the lower in dark blue. This was then gone over in black to find some approximate shapes and the final layer (the bra design) was done in pink for the lower stress and purple higher stress. These were then built upon to create the final design.

Calculation of theoretical fabric stress

Theoretical model

Calculation of internal pressure

Final design

This idea was taken from the simulation. It focuses the majority of its support on the areas that were taking a higher stress in the simulation. The design almost acts as a cradle to the breast with elastic or thicker fabric and joins together at the central gore. It is a similar shape to the butterfly design from the earlier prototypes and the optimum taping method from the scans.

Materials testing + decision

Material requirements

Only put 6-10 N of stress on the body when stretching

Be able to stretch 28%

Biodegradable

Less embodied energy

Withstand loads of 1.5 - 5.3 kg

Withstand a washing machine (30 degrees)

Not degrade with sweat, perfume and detergent

Feel soft on the skin

Moisture wicking and breathable

Fell luxurious

Be something you want to wear

Be easy to sew and machine

I conducted my own version of the BBE test to ascertain the required level of user comfort (how much tensile force is comfortable to take on the ribcage, when the bra is stretch round the body) and create some material limitations (informed by current bras on the market), I stretched a range of bras of different sizes. Attaching the bra to a luggage scale and stretching it to the correct length, at which, the force applied was found.

After looking into the properties I conducted further research into bamboo fabrics and lyocell and decided a mixture of the two was best. Bamboo lyocell (also known as monocel) combines the advantages of the other two fibres, with none of the negatives. It is made in a similar process to rayon and has similar properties while being produced in a much more environmentally friendly way. It is crushed like in the mechanical process, but then non-toxic amine oxide is used to break it down rather than toxic chemicals. This and the water used in the process is saved to be used again as in a closed loop cycle. The material is also not chemically altered by the process like rayon, meaning that it is still biodegradable at the end of its life. It still maintains the silky, luxurious feel of rayon but is a lot kinder to the skin and the planet. It is also biodegradable meaning the bra would be.

I conducted a CES analysis with the naturally derived fibres and nylon. It seemed that PLA had a similar yield strength and the cellulosic fibres (anything made in a rayon-like process had a similar elongation and yield strength. Therefore I did a deeper analysis into these fibres seen below.

Underwire making

To prototype the underwires quickly, I decided to 3D print the designs made in Fusion 360, to be able to decide the best shape and thickness.

I implemented all the learnings from the user testing and then simulated the final underwires. The forces applied were the tension of the cup that was calculated previously and a 10 N force pulling it back (as found from the band comfort zone tests previously). It resulted in having a safety factor of 15, so it was deemed a good shape to use. .

This initial underwire, or under-bust support, was very effective but was very rigid to wear and it felt like there was too much material on the side of the breast. therefore, I designed new shapes and printed thinner supports.

This iteration was the most successful and the best thickness in terms of striking a balance between support and comfort was 2mm. I then tested this on some of the people I’d scanned previously and decided it was the design to carry forward.

Underwire material decision

Similar to the way that the bra material was decided, I carried out a CES analysis of potential underwire materials and then looked into them all further. I decided to go with PLA as it is compostable and is easy to print. I made the rings, sliders and hooks out of the same material, meaning that the bra was 100% compostable.

Business

Hero image

Final underwire shape

Originally I made the rings + sliders too thin so they distorted, so I doubled the thickness.